“In 2008 I decided to create Spiruline Solaire in the mountains of the northern Provence. The spot is sunny but at 3000ft altitude and without electricity. Growing tropic algae under these conditions seemed quite a challenge.

Special greenhouse design was necessary to keep the culture warm during night and all steps of the harvest process had to be done with a little solar electricity.

As I was going ahead with a small budget, the local waste-recycle-station turned out to be an important source of all kinds of material. Especially old bicycles became all kind of mechanic devices. Empty propane bottles did a good job too for the vacuum pressing machine.

In France small spirulina farms have been spreading all over the country for the last twenty years. Most of them are related through a national association where experience and knowledge is freely shared. After a while I got more and more attention with my works and eventually some colleagues asked me to build harvest machines for them.

I started with having workshops for transforming sausage-presses to spirulina-extruders. Later I offered building vacuum presses though I was mainly working on the major part of the harvest: the rotation filter.

At that period harvesting spirulina meant gripping the green stuff off huge filter screens during several hours a day. Of course many inventions where made to solve this problem: vacuum tables, vibrating tables, benched filters, centrifuge filters, rotation filters, but none of them reached the step of being commercialized.

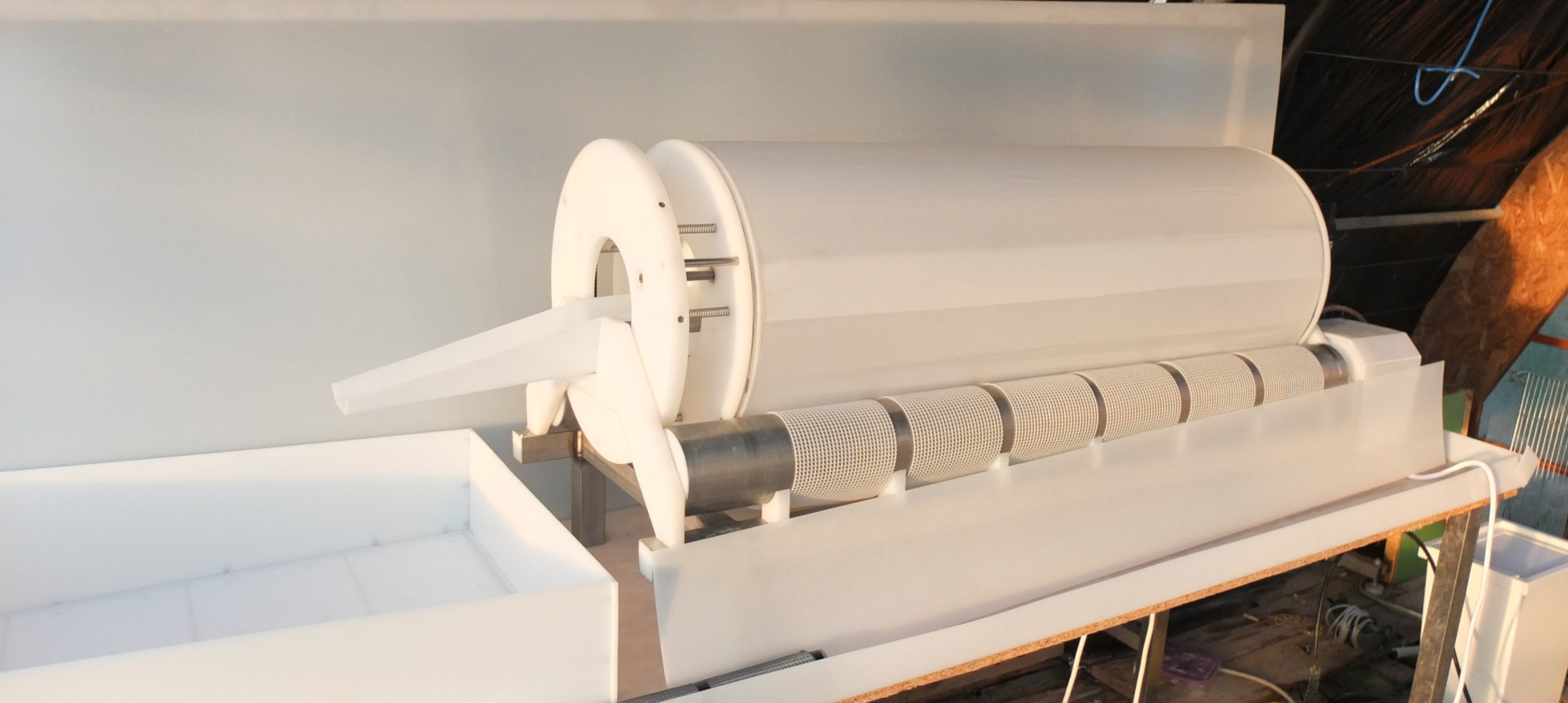

My own research led me to an hybride rotation filter, where the cylinder was both solid enough to contain a deep pool which is essential for good filtering and circeled by nothing but filter screen for easy cleaning.

It took three years to get the final touch, now made of polyehthylen and stainless steel, but finally a reliable, solid and easy handling machine was available at a reasonable cost.

The business started right away and after only one year I had to create a proper company for it.